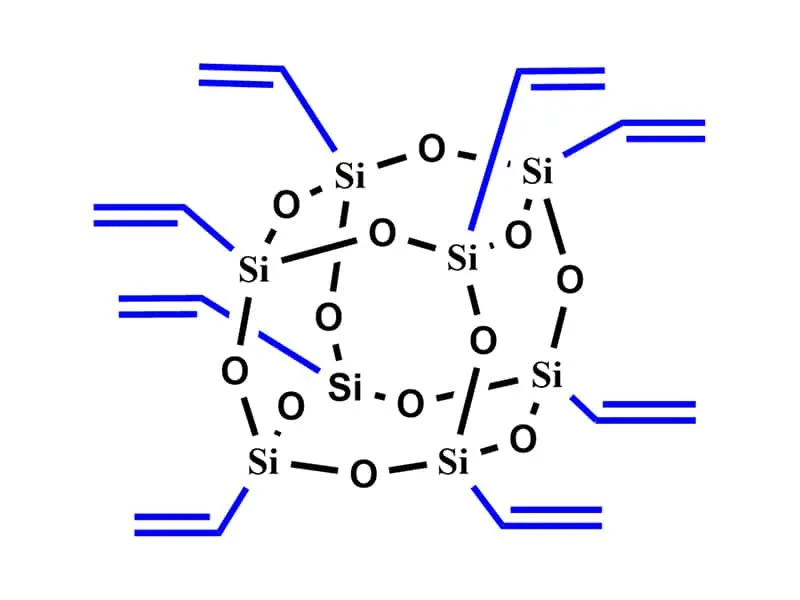

Octavinyl POSS (OV-POSS) is an organic-inorganic hybrid nanomaterial with a silsesquioxane cage core and eight vinyl functional groups at its corners. While most of the cages had a (SiO₁.₅)₈ core, some cages with a (SiO₁.₅)₁₀ or (SiO₁.₅)₁₂ core were also present.

This product exhibits high thermal stability and is widely used as a nanoscale additive to enhance the mechanical, thermal, and chemical resistance properties of polymers and composites. Its molecular structure provides excellent reactivity, thermal stability, and mechanical reinforcement, making it widely used in polymer modification, composites, and functional coatings.

*This product is co-developed and jointly produced with Shenzhen Institute for Advanced Polymer Materials (SIAP).

Octavinyl Polyhedral Oligomeric Silsesquioxane

69655-76-1

| Property | Description |

| Chemical Name | Octavinyl Polyhedral Oligomeric Silsesquioxane |

| CAS Number | 69655-76-1 |

| Molecular Weight | ~ 633 g/mol |

| Melting Point | > 350 °C |

| Appearance | White powder |

| Density | 1.22 g/cm³ |

| Solubility | Soluble in chloroform, toluene, THF; slightly soluble in ethanol; insoluble in water |

| Purity | ≥ 98.0% |

Octavinyl POSS is highly versatile due to its reactive vinyl groups, which allow it to participate in various chemical reactions, such as polymerization or crosslinking, with organic polymers. This compatibility enables it to be incorporated into a wide range of materials, including UV-curable resin systems and liquid silicone rubber, epoxy, acrylic, and polyurethane resins.

Polymer Modification: Enhances thermal stability and mechanical strength in silicone rubbers, epoxies, and acrylic resins via radical polymerization or addition reactions.

Nanocomposites: Acts as a crosslinking agent for high-performance coatings and adhesives. Used as a filler to improve hardness and wear resistance of epoxy resins or polyurethanes, suitable for aerospace applications.

Functional Coatings: Applied in hydrophobic or corrosion-resistant coatings to enhance surface properties.

High-Temperature Materials: Used in aerospace and automotive industries for heat-resistant components.

Note: This document does not contain the product safety information necessary for safe use. Prior to handling, please review the product and material safety data sheets along with hazard information. To obtain material safety data information, reach out to SIAP.

Keep away from fire and direct sunlight.

Store in a cool, dry, and well-ventilated area, away from direct sunlight and high temperatures.

It has 12 months shelf life in closed containers.

Recommended storage temperature: 0°C - 25°C.

Avoid contact with strong oxidizers or acidic substances.

Products beyond the shelf life can be usable, if quality check passed.

Standard Packaging: 100 g/bag, 500 g/bag, 1 kg/bag, 25 kg/bag.

Packaged in light-proof sealed containers; custom packaging available upon request.

* Required fields