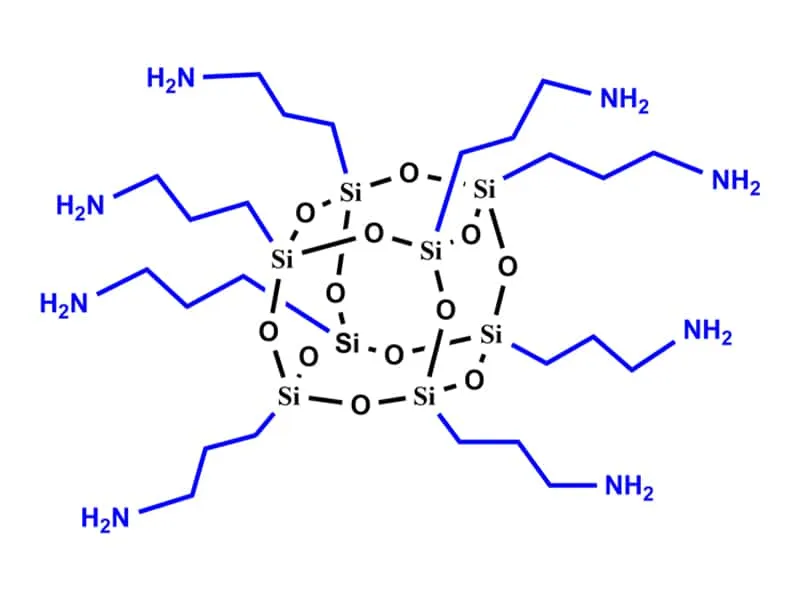

Aminopropyl-POSS (AM-POSS) is an amino-functionalized polyhedral oligomeric silsesquioxane nanomaterial. It is an organic-inorganic hybrid nanomaterial featuring a silsesquioxane cage core with eight aminopropyl functional groups (-CH₂CH₂CH₂NH₂) attached to its corners. While most of the cages had a (SiO₁.₅)₈ core, some cages with a (SiO₁.₅)₁₀ or (SiO₁.₅)₁₂ core were also

present.

Its reactive amine groups and 3D cage structure (~1.5-2nm) enhance interfacial compatibility, mechanical properties, and thermal stability in polymer matrices. Ideal for epoxy curing, biomedical material modification, nanocomposite reinforcement, and surface modification.

*This product is co-developed and jointly produced with Shenzhen Institute for Advanced Polymer Materials (SIAP).

Octaaminopropyl Polyhedral Oligomeric Silsesquioxane

150380-11-3

| Property | Description |

| Chemical Name | Octaaminopropyl Polyhedral Oligomeric Silsesquioxane |

| CAS Number | 150380-11-3 |

| Molecular Formula | (H₂NCH₂CH₂CH₂)₈Si₈O₁₂ |

| Molecular Weight | ~ 865 g/mol |

| Appearance | White powder |

| Density | ~1.20 g/cm³ |

| Solubility | Soluble in water, ethanol, DMF; slightly soluble in THF; insoluble in hexane |

| Purity | ≥ 98.0% |

The aminopropyl groups endow AM-POSS with exceptional reactivity and versatility, as the primary amine (-NH₂) functionalities can participate in hydrogen bonding, nucleophilic reactions, or serve as sites for further chemical modification, such as grafting onto polymers or forming ionic interactions. This makes it highly compatible with a variety of systems, including epoxy, polyurethane, and polyamide resins, where it acts as a crosslinking agent, toughening agent, or surface modifier. Thus, AM-POSS is widely explored in materials science and nanotechnology for applications such as high-strength composites, coatings, and adhesives.

Polymer Modification: Acts as a reactive additive to enhance crosslinking and mechanical properties of epoxy resins or polyurethanes, suitable for high-performance coatings. Epoxy curing agent (1-3% loading, enhances curing rate and heat resistance) Silicone rubber reinforcement (improves tensile strength and tear resistance)

Composites: Improves interfacial bonding between fillers (e.g., carbon fiber, silica) and matrices, applicable in aerospace composites.

Surface Functionalization: Used to prepare hydrophilic or antibacterial surfaces, suitable for biomedical materials or water treatment membranes. Biocompatible coatings (for medical device surface modification)

Dye/drug carrier (amine-mediated functional molecule loading)

Note: This document does not contain the product safety information necessary for safe use. Prior to handling, please review the product and material safety data sheets along with hazard information. To obtain material safety data information, reach out to SIAP.

Keep away from fire and direct sunlight.

Store in a cool, dry, and well-ventilated area, away from direct sunlight and high temperatures.

It has 12 months shelf life in closed containers.

Recommended storage temperature: 5°C - 25°C.

Avoid prolonged contact with strong acids, oxidizers, or carbon dioxide (to prevent amine reaction or degradation).

Products beyond the shelf life can be usable, if quality check passed.

Standard Packaging: 100 g/bag, 500 g/bag, 1 kg/bag, 25 kg/bag.

Packaged in light-proof sealed containers; custom packaging available upon request.

* Required fields