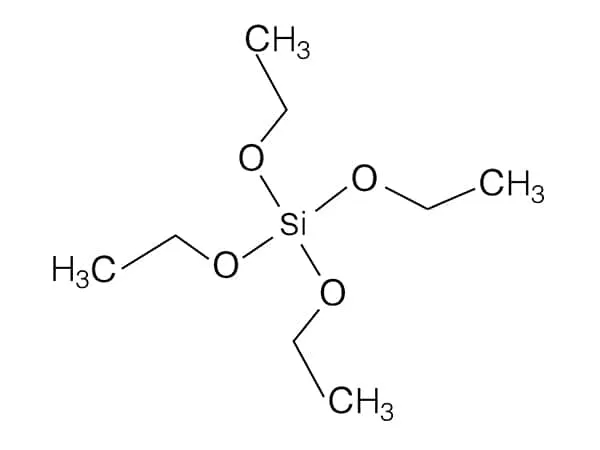

Ethyl Silicate 40, also known as ethyl polysilicate or simply "ES-40," is a specific type of ethyl silicate compound. It is characterized by having an average of approximately 40% silicon dioxide (SiO₂) content by weight. Ethyl Silicate 40 is composed of silicon (Si) bonded to ethoxy groups (C₂H₅O-) and is commonly represented by the chemical formula Si(OC₂H₅)₄.

Key characteristics and uses of Ethyl Silicate 40 include:

Binder and Coating Applications: It is widely used as a binder or resin in the formulation of coatings, paints, and protective layers. Upon application and subsequent curing, it forms a dense and durable silica network that provides excellent resistance to moisture, chemicals, and weathering.

Silica Gel and Aerogel Production: Ethyl Silicate 40 serves as a precursor in the production of silica gels and aerogels through the sol-gel process. This process involves hydrolysis of the ethoxy groups in the presence of water, followed by condensation to form a solid silica network with high porosity and low thermal conductivity.

Ceramics and Investment Casting: It is used in ceramics and investment casting processes as a binder for ceramic materials and molds due to its ability to form strong, heat-resistant bonds with ceramic particles.

Industrial Applications: Ethyl Silicate 40 finds applications in industries such as construction (for protective coatings on concrete and stone), electronics (for encapsulating electronic components), and aerospace (for thermal insulation coatings).

Crosslinking Agent: It can be used as a crosslinking agent in organic-inorganic hybrid materials, where it enhances mechanical strength and thermal stability.

Ethyl Silicate 40 is valued for its versatility in producing silica-based materials with tailored properties, making it a critical component in various advanced material applications across industries. Its ability to form durable and chemically resistant coatings and matrices contributes significantly to its widespread use in industrial and research settings.