Stability of aqueous silane solutions varies from hours for the simple alkyl silanes to weeks for the aminosilanes. Poor solubility parameters limit the use of long chain alkyl and aromatic silanes by this method. Distilled water is not necessary, but water containing fluoride ions must be avoided.

Bulk deposition onto powders, e.g. filler treatment, is usually accomplished by a spray-on method. It assumes that the total amount of silane necessary is known and that sufficient adsorbed moisture is present on the filler to cause hydrolysis of the silane. The silane is prepared as a 25% solution in alcohol. The powder is placed in a high intensity solid mixer, e.g. twin cone mixer with intensifier. The solution is pumped into the agitated powder as a fine spray. In general this operation is completed within 20 minutes. Dynamic drying methods are most effective. If the filler is dried in trays, care must be taken to avoid wicking or skinning of the top layer of treated material by adjusting heat and air flow.

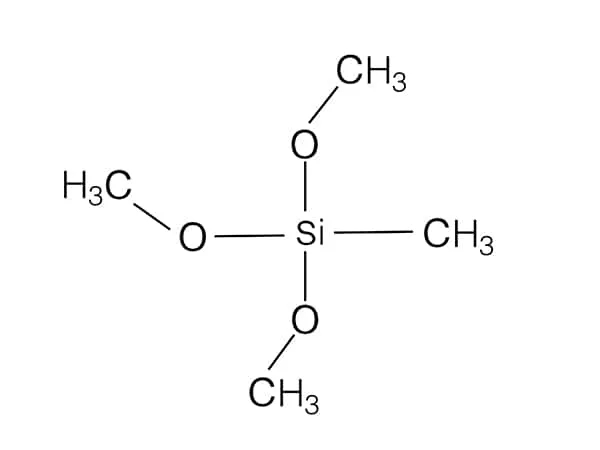

Integral blend methods are used in composite formulations. In this method the silane is used as a simple additive. Composites can be prepared by the addition of alkoxysilanes or silazanes to dry-blends of polymer and filler prior to compounding. Generally 0.2 to 1.0 weight percent of silane (of the total mix) is dispersed by spraying the silane in an alcohol carrier onto a preblend.

The addition of the silane to the non-dispersed filler is not desirable in this technique since it can lead to agglomeration. The mix is dry-blended briefly and then melt compounded. Vacuum devolatization of byproducts of silane reaction during melt compounding is necessary to achieve optimal properties. Properties are sometimes enhanced by adding 0.5–1.0% of tetrabutyl titanate or benzyldimethylamine to the silane prior to dispersal.

Deposition as a primer is employed where a bulk phase is required as a transition between a substrate and a final coating. The silane is dissolved at 50% concentration in alcohol. One to three molar equivalents of water are added. The mixture is allowed to equilibrate for 15-20 mins. then diluted to 10% concentration with a higher boiling point solvent. Materials to be coated with the primer are dipped or sprayed and then cured at 110–120°C for 30–45 mins.

Chlorosilanes such as SIV9110.0 may be deposited from alcohol solution. Anhydrous alcohols, particularly ethanol or isopropanol, are preferred. The chlorosilane is added to the alcohol to yield a 2–5% solution. The chlorosilane reacts with the alcohol producing an alkoxysilane and HCl. Progress of the reaction is observed by halt of HCl evolution. Mild warming of the solution (30–40°C) promotes completion of the reaction. Part of the HCl reacts with the alcohol to produce small quantities of alkyl halide and water. The water causes formation of silanols from alkoxysilanes. The silanols condense on the substrate. Treated substrates are cured for 5–10 mins. at 110°C or allowed to stand 24 hours at room temperature.

Chlorosilanes and silylamines may also be employed to treat substrates under aprotic conditions. Toluene, tetrahydrofuran, or hydrocarbon solutions are prepared containing 5% silane. The mixture is refluxed for 12–24 hours with the substrate to be treated. It is washed with the solvent.The solvent is then removed by air or explosion-proof oven drying. No further cure is necessary.

This reaction involves a direct nucelophilic displacement of the silane chlorines by the surface silanol. If monolayer deposition is desired, substrates should be predried at 150°C for 4 hours.

Bulk deposition results if adsorbed water is present on the substrate. This method is cumbersome for large scale preparations and rigorous controls must be established to ensure reproducible results. More reproducible coverage is obtained with monochlorosilanes.

Silazanes such as SIH6110.0 and SID4612.0 may be used as treatments in concentrated form or as 10–20% solutions in aprotic solvents. In some applications parts are exposed for 5–10 minutes by dipping or in microelectronics by spin-on techniques. Optimum reactivity is as 30–50°C. An alternate method of treatment is to expose parts to 50°C vapor for 2–6 hours. Ammonia is the byproduct of silazane reaction and areas should be ventilated