Smarter Composites, Lower Costs

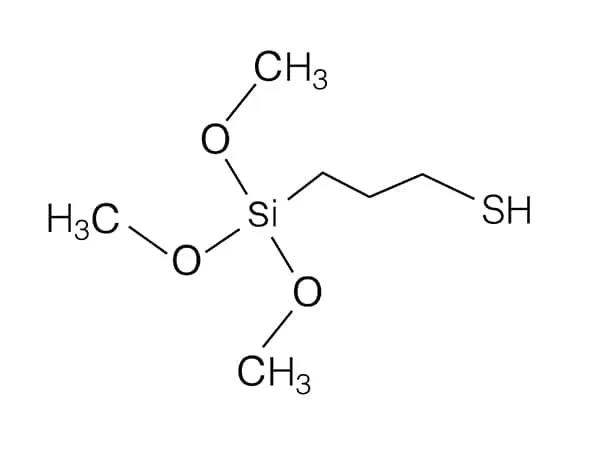

Fillers like silica or talc reduce material costs but often weaken polymers due to poor dispersion. Silane crosslinkers transform fillers into active reinforcement agents.

In polyethylene (PE) pipes, silica treated with vinyl silanes crosslinks with the PE matrix during extrusion. This increases pressure resistance by 35%, preventing leaks in gas pipelines.

For rubber tires, bis-(triethoxysilylpropyl) tetrasulfide (TESPT) crosslinks silica with styrene-butadiene rubber, cutting rolling resistance by 20% and improving fuel efficiency.

Even biodegradable plastics benefit: crosslinked starch-silane composites exhibit 50% higher tensile strength, enabling eco-friendly packaging.