Inorganic fillers (e.g., silica, calcium carbonate) are added to plastics, rubbers, and ceramics to reduce costs and enhance properties. However, poor filler-matrix compatibility limits performance.

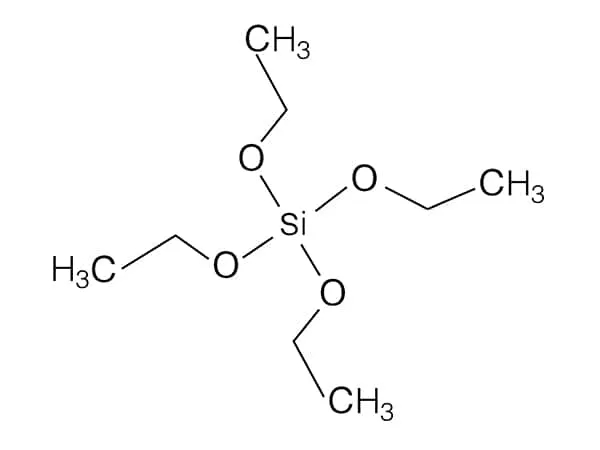

Silane coupling agents solve this by modifying filler surfaces. For instance, treating silica with octyltriethoxysilane replaces hydrophilic Si-OH groups with hydrophobic chains, improving dispersion in polypropylene. This increases tensile strength by 40% while reducing viscosity during processing.

In rubber tires, sulfur-containing silanes (e.g., TESPT) bond silica to styrene-butadiene rubber, enhancing abrasion resistance and fuel efficiency. Such innovations drive sustainable material design across industries.