Glass fiber-reinforced composites are widely used in automotive, aerospace, and construction industries due to their high strength-to-weight ratio. However, the weak interface between hydrophilic glass fibers and hydrophobic polymer matrices often leads to poor mechanical performance.

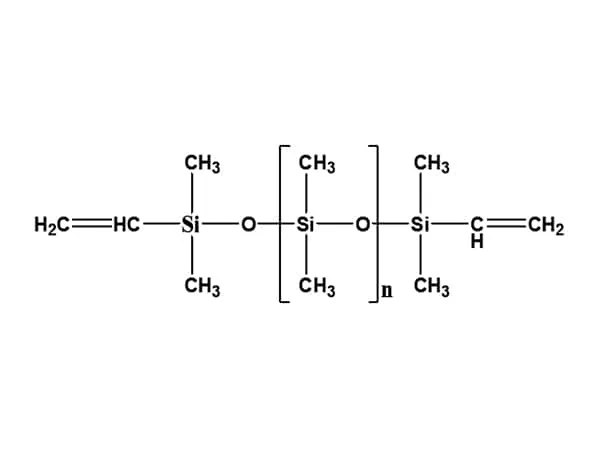

Silane coupling agents address this challenge by forming a chemical bridge. The hydrolyzable alkoxy groups in silanes bond with hydroxyl groups on the glass surface, while their organofunctional groups (e.g., amino, epoxy) react with the polymer resin. This dual functionality enhances interfacial adhesion, improving tensile strength, flexural properties, and moisture resistance. For example, amino silanes are commonly used in epoxy-based composites, resulting in up to 30% higher durability in harsh environments.

By optimizing silane selection and application methods, manufacturers ensure composites meet rigorous industrial standards.