Silane crosslinkers are revolutionizing anti-corrosion coatings by creating dense, hydrophobic networks on metal surfaces. These hybrid organic-inorganic layers provide superior barrier properties, outperforming traditional chromate-based treatments.

Key Applications

Automotive and Marine Coatings

Technology: Bis-[3-(triethoxysilyl)propyl]tetrasulfide forms crosslinked siloxane layers on steel and aluminum.

Performance: Extends salt spray resistance to 2,000+ hours (ASTM B117), replacing toxic chromate conversion coatings.

Architectural Coatings for Aluminum

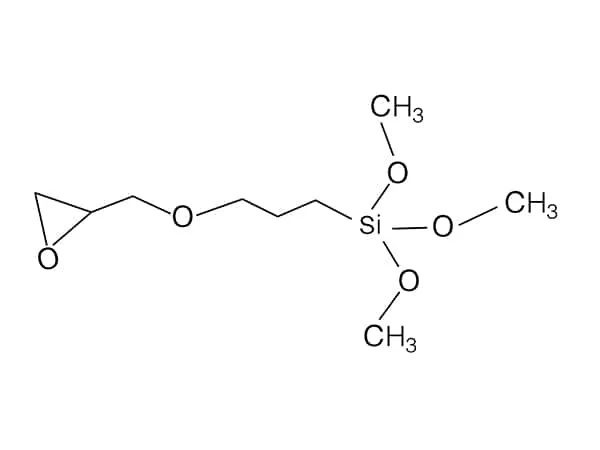

Function: Glycidoxypropyltrimethoxysilane enhances adhesion of powder coatings to anodized aluminum.

Result: Reduces coating blistering in humid climates (ISO 6270-1 compliance).

Oil & Gas Pipeline Protection

Innovation: Fluorinated silane crosslinkers create ultra-low surface energy coatings to repel water and hydrocarbons.

Product Advantages

Rapid Curing: Ambient or low-temperature curing (80–120°C) reduces energy costs.

Multi-Substrate Compatibility: Effective on steel, aluminum, copper, and alloys.

Case Study

A European pipeline operator reduced maintenance costs by 60% after adopting our fluorosilane-based coating, which withstood acidic soil (pH 3.5) and H₂S exposure for 5+ years.

Conclusion

Silane crosslinkers deliver next-gen corrosion protection with environmental compliance. Explore our portfolio to safeguard critical infrastructure.