Stable-high quality silanes by DCS automatic production line

Clients covering 57 countries and regions

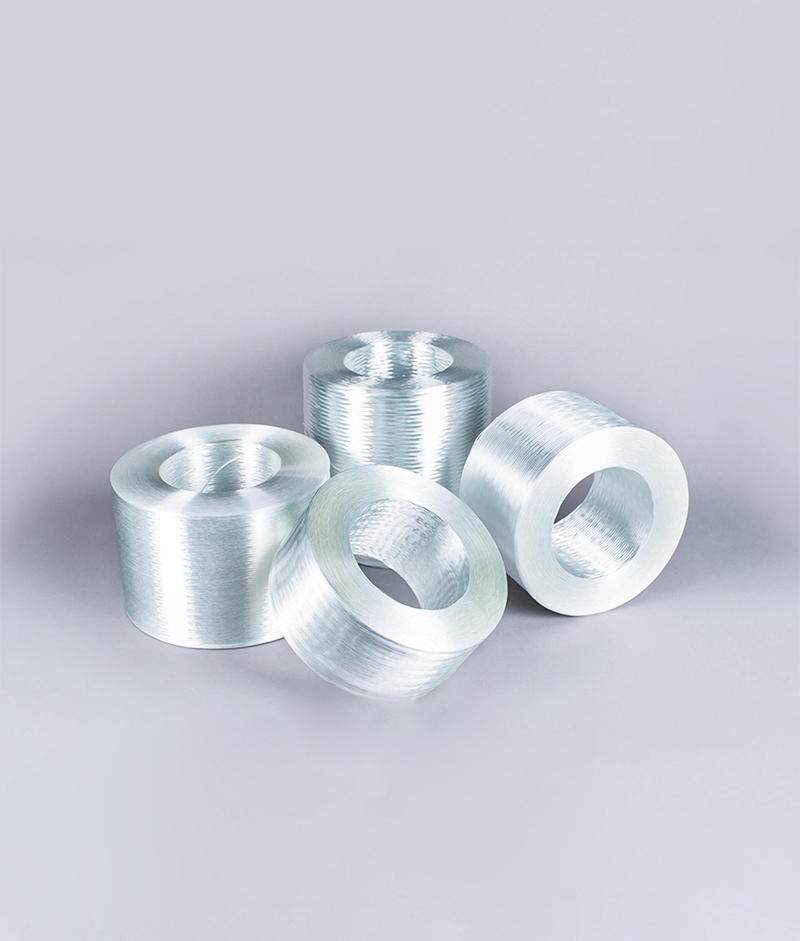

They are widely used in glass fiber, electronics, wind power, daily necessities, chemical industry, coatings, adhesives, XLPE Electrical cables and hot water pipes, oilfield drilling, textiles, rubber.

Hengda Chemical, headquartered in Gaizhou City, Liaoning Province. We are the first silane manufacturerin China since 1965.

Products are sold all over China, and exported to North America, Europe, Japan, South Korea, Australia, South America, the Middle East, India, Southeast Asia, Russia, etc., well trusted by customers.

350000 tons per year

Customers over 57 countries

More than 50 honorary certificates

More than 100 patents

We are excited to invite you to connect with our team at ECS 2025, Europe’s leading coatings industry event, held from March 25–27, 2025, at Nuremberg Messe, Germany. Visit Booth 3-127 to explore our specialized product range, including Silane Coupling Agents, Cross-linking Agents, and Silicone Fluids, and discover how we can elevate your projects with tailored technical support.

HENGDA to Exhibit at INTERLAKOKRASKA 2025 in Moscow

HENGDA will attend KHIMIA 2024 Exhibition

The choice of organic Silane coupling agents generally with test data of organic Silane coupling agent on the face, accurate. It is not easy to predict silane coupling agents. After using organic silane coupling agent increases the bond strength is a combination of a series of complicated factors, such as infiltration, surface energy and boundary layer adsorption, adsorption, polarity of acid-base interaction, etc.

The role and effect of silane coupling agent to be recognized and sure, but why a tiny amount of coupling agent on interface such a significant impact on the performance of the composite materials, haven’t a complete set of coupling mechanism to explain. Silane coupling agents on the interface between two materials with different properties of mechanism has a lot of research, and put forward the chemical and physical sorption. The chemical theory is the most ancient but is so far a theory is considered to be more successful.

The theory is that coupling agent containing a chemical functional groups, with the silanol groups on the surface of the glass fiber and other inorganic filler on the surface of the molecular form covalent bond; In addition, the coupling agent also contains a kind of different functional groups and polymer molecular bonding, in order to obtain the good interface bonding, coupling agent is to play a bridge of mutual connection between inorganic and organic facies role. The silane coupling agent as an example to show the valency theory. Such as ammonium propyl triethoxy silane, when use it first with inorganic filler (such as glass fiber, etc.), silane hydrolysis into silanol first, then the silicon alcohol-based and inorganic filler surface dehydration reaction.

The silane coupling agent directly added to the adhesive composition, as the matrix resin for the amount of general amount of 1 ~ 5%. After the glue by molecular diffusion effect, coupling agent molecular migration to the bonding interface coupling effect. For curing adhesives, glue should be placed after a period of time for curing, so that the coupling agent to complete the migration process, in order to obtain good results. Actual use, often coupling agent on the surface to form a sediment, but the real work is monomolecular layer, therefore, Silane coupling agents usage need not too much.

Hengda Silane Technology is one of the leading silane manufacturers in China.

Modified silanes adhesives were developed and launched in Japan during the 80’s, due to the great advantage of these elastic adhesive compared to polyurethane adhesives, its use is highly increase both Europe and America markets.

Modified silanes are one component adhesives which react and cure under the action of moisture, during its curing process by polycondensation this type of adhesives emit methanol and once cured acquire elastic properties and typical strength of an elastomeric material.